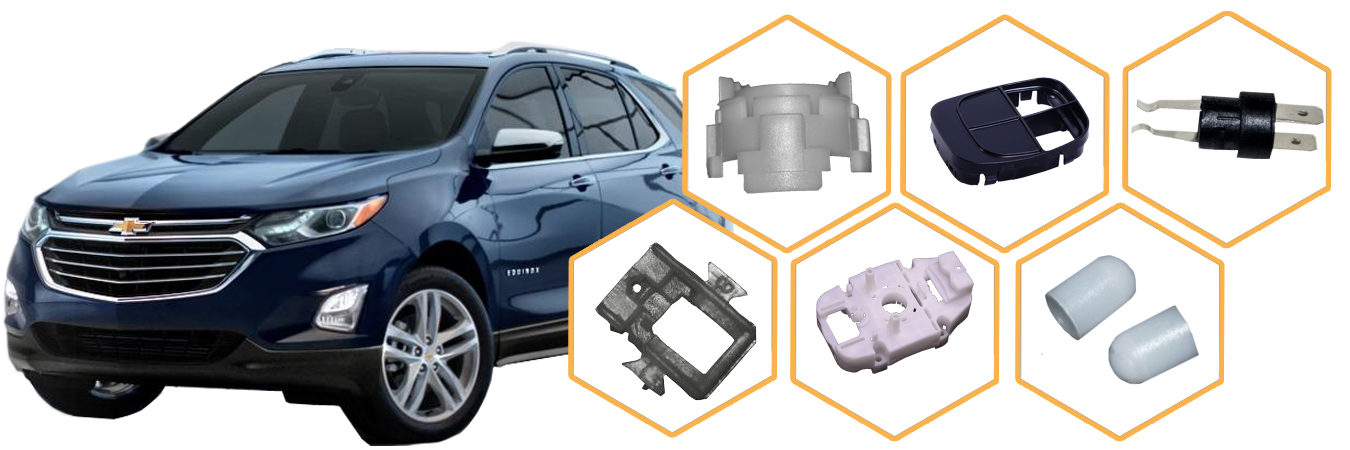

Plastic Injection Moulds, Automotive Moulded Products, Insert Moulding Components & more..

"We are Manufacturer, Supplier, Exporter of Insert Moulding, Plastic Insert Moulding, Over Moulding, Insert Moulding Components, Terminal Insert Moulding, Precise Plastic Insert Moulding Components, Plastic Engineering Material Moulding, Intricate Plastic Moulded Parts, Plastic Moulds, Moulds For Plastic Insert Moulding Components, Wire Insert Moulding, Bobbins Coil Winding Plastic Bobbins, Inductor Coil Winding Bobbins, Transformer Coil Winding Bobbins, Flasher Housings, Plastic Housings, Plastic Components For Industrial Component, Plastic Components For Electrical Application, Plastic Components For Auto Electronics Application, Plastic Components For CDL Hosing, Insert Moulded Connectors, Wire Moulded Connectors, Termister Moulded Connectors, Terminal Insert Moulding Connectors, Wire Insert Moulded Connectors, Automotive Sensor Moulded Parts, Automotive Moulded Lighting Parts, Automotive Moulded Lighting Components, Automotive Moulded Electronic Parts, Precision Moulding Parts, Precision Moulding Components, Thermoplastic Elastomer Products, TPE Products and our setup is situated in Pune, Maharashtra, India. We serve the customers from all over India also Asian, African and USA Countries."

About AIM PLAST

Established in 1996, AIM PLAST specializes in the areas of innovative solutions for mould development & moulding of precise plastics injection moulded components optimized for quality & cost based on our theme "Ideation to Actualization" with strong focus on customer delight and green manufacturing practices.

Our two decades of experience in providing tooling & moulding solutions for precise injection moulding components with strong adherence to best manufacturing practices backed by the data driven approach results in end-to end process visibility, reliability & superior product quality for our customers.

We provide Innovative & cost effective solutions for replacement of Neoprene, Nitrite, EPDM & few other thermoset rubber components to "Thermoplastics Elastomers-TPE", thereby increasing the productivity, Durability & Quality of components reducing the Carbon footprint & optimizing the resources utilized in the process.

AIM PLAST shall be an ideal organization and technology leader in its chosen fields, synergizing growth, work-life balance of all stake-holders, being a socially and environmentally responsible company, thereby setting an example for others to follow.

- To manufacturer best in class precision plastics products optimized for quality & cost.

- By providing innovative indigenous solutions to customers.

- Protecting dignity & self respect of employees.

- Customer satisfaction is at most importance.

- Humans are precious resources.

- Talent is important & needs to be nurtured.

- Society has helped to form & evolve the company to what it is.

- ‘Goodness’ Prevails every where - Needs harnessing.

We are a medium-sized 1st generation enterprise based in Pune, Maharashtra, India. 2 decades of experience in the manufacturing of thermoplastic Injection molds and supply of components. Our dedicated team of experts draws on this experience to get the very best results and trust for our customers

Tool ManufacturingOur infrastructure with special customised small moulding machines can produce high quality injection parts with insert and terminal moulding. We development the Moulds, we understand the value that bring comprehensively managing the process from end to end throughout the life.

Plastic PartsBased on our many years of experience, we are able to offer you a large portfolio of standard components made from various plastic materials. And should you require individually dimensioned plastic parts with special characteristics, we are also happy to work with you on developing the perfect injection-moulding solution and small-scale series production.

IATF 16949:2016 standard

Our Products

Automotive Sensor Moulded Parts

Our engineers will collaboratively review and enhance the part designs to ensure optimization for volume production. We aim to become complete solution provider for the engineering needs and capabilities, working closely with the design, project management, mold making and into production and further production support. Our team will consistently work for innovative solutions that will not only deliver your needs but exceed your expectations

Read MoreAutomotive Moulded Lighting Parts / Components

Our highly experienced advanced engineering team work in tandem with our processing and manufacturing experts to optimize the part design and all other aspects of fixturing, processing and deliver your parts for next process when and where you need them. Collaborative design optimization as per the engineering disciplines increases efficiencies and adds value to customers.

Read MoreAutomotive Moulded (Molded) Electronic Parts

Our highly experienced advanced engineering team work in tandem with our processing and manufacturing experts to optimize the part design and all other aspects of fixturing, processing and deliver your parts for next process when and where you need them. Collaborative design optimization as per the engineering disciplines increases efficiencies and adds value to customers.

Read MoreAutomotive Moulded (Molded) Switches

Our infrastructure with special customised small moulding machines can produce high quality injection parts with insert and terminal moulding. We development the Moulds, we understand the value that bring comprehensively managing the process from end to end throughout the life. Aim Plast is equipped with the latest technologies including high speed CNC machine centre, ZNC EDM and precision grinding. High accuracy validation occurs throughout the tool build and on into production where QA needs accuracy and reliability.

Read MoreThermoplastic Elastomer (TPE) Products

After lot of research and innovation and experiments we have developed strong platform of the know-how for replacement of thermosetting rubber to TPE (Thermo Plastic Elastomer) Key advantages of high productivity, ready to use parts without post moulding environment friendly, recyclable, non-hazardous & less carbon foot print. Completed projects with customers which has been effectively resulted cost saving for customers

Read More