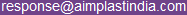

Insert Moulding Parts / Components

We are Manufacturer, Supplier, Exporter of Insert Moulding Parts, Insert Moulding Components, Over Moulding Parts, Insert Moulding Components, Insert Moulding, Plastic Insert Moulding, Over Moulding, Terminal Insert Moulding, Precise Plastic Insert Moulding Components, Plastic Engineering Material Moulding, Intricate Plastic Moulded Parts, Plastic Moulds , Moulds For Plastic Insert Moulding Components, Wire Insert Moulding and our setup is situated in Pune, Maharashtra, India.

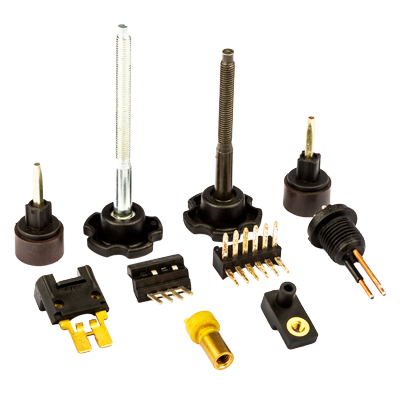

Insert molding is a process in which plastic is injected into a mold that contains pre-placed insert. The result of insert molding is a single molded plastic piece with an insert surrounded by the plastic. Inserts can be made of metals or different types of plastic. Insert molding is used in many industries. Applications of insert molding include insert-molded housings for various applications, threaded fasteners, filters, electrical and electronic components.

Aim Plast’s unique speciality and expertise is to design and develop the moulds for products with inserts, terminal and wires molded with high end engineering plastics for automotive switches and sensors. Our design experts provide complete solution for development of moulds and specially designed machines for insert moulding.

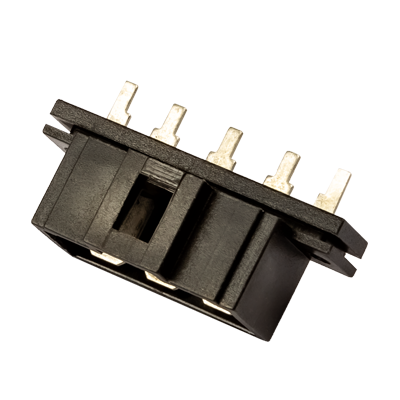

Over Moulding Parts / Components

The process of over moulding where a single part is created using two or more different materials in combination. Typically, the first material, sometimes referred to as the substrate, is partially or fully covered by subsequent materials (over mold materials) during the manufacturing process. We are specialised in moulding of soft material on hard material for the parts like automobile knobs and over moulding of sensor assly to connector with 2 separate plastic materials having different melting temperature. Our skilful approach can help to design & develop components with all criticality and our customers prefer Aim Plast for their requirments.